eQi Bioenergy

A solution to fight climate change and improve

energy self-sufficiency of communities

eQi Bioenergy technology uses most agricultural residues and mixtures as feedstock for the efficient production of bioethanol at a low cost

Our small-scale technology is radically different from large-scale stakeholders’ proposals that require large capital investments with long implementation times. Our technology will push forward a just energy transition, placing in the first instance, the community welfare by producing bioethanol for local consumption, whilst supporting national CO2 emissions reduction policies.

Paradigm shift to fight climate change

We are less than 3 years from reaching the point at which greenhouse gas will cause a planetary increase beyond 2°C by 2100, causing irreversible damage to nature as we know it. We should move towards solutions to aggressively fight climate change in the short term. People’s welfare is intimately linked to the environment’s well-being.

According to the International Energy Agency, fossil petrol consumption must decrease from 90% to 12% and biofuel consumption increase from 7% to 14% to achieve net zero CO2 emissions by 2050. Local production and consumption of biofuels will certainly contribute to meeting these targets.

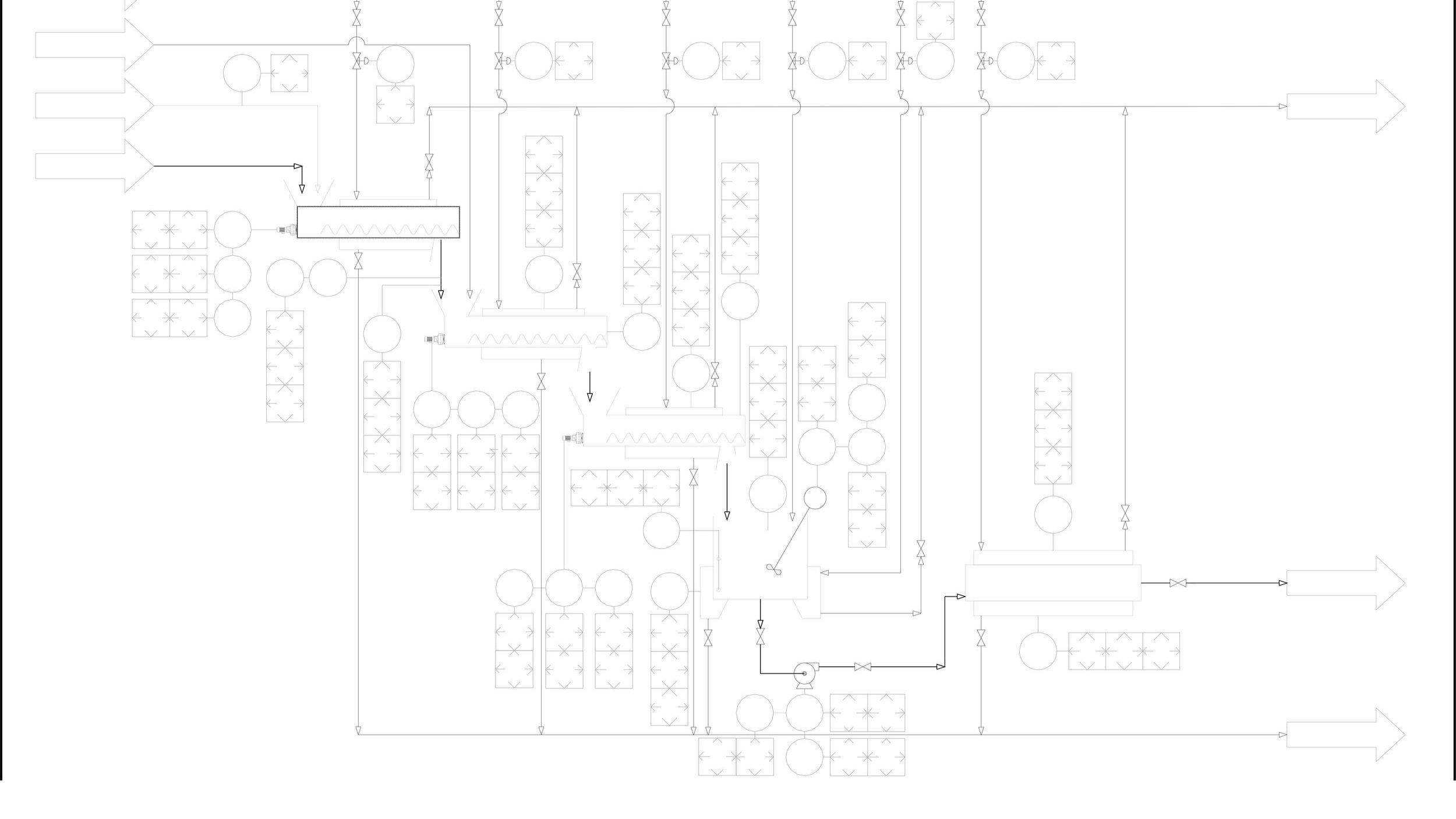

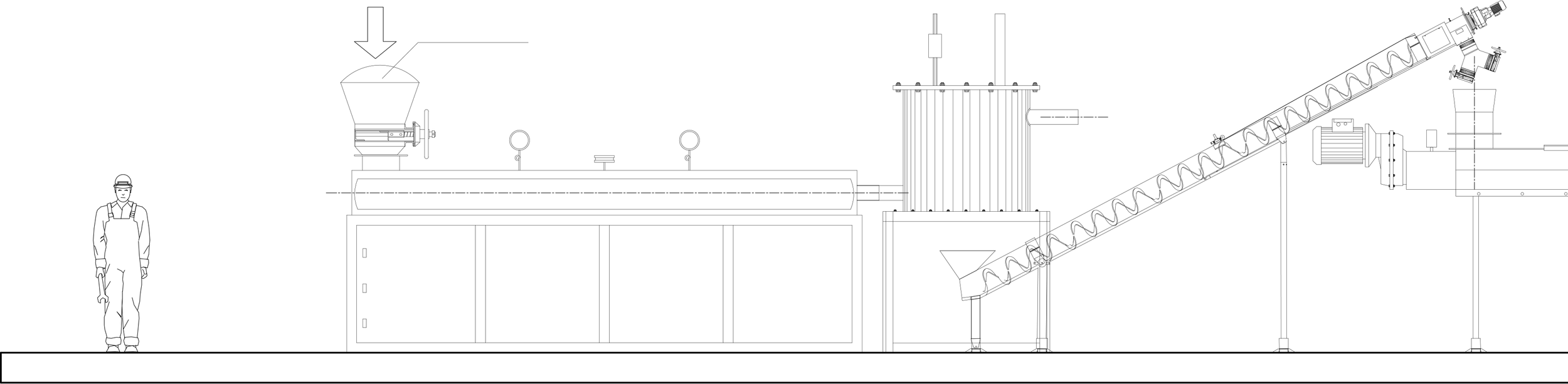

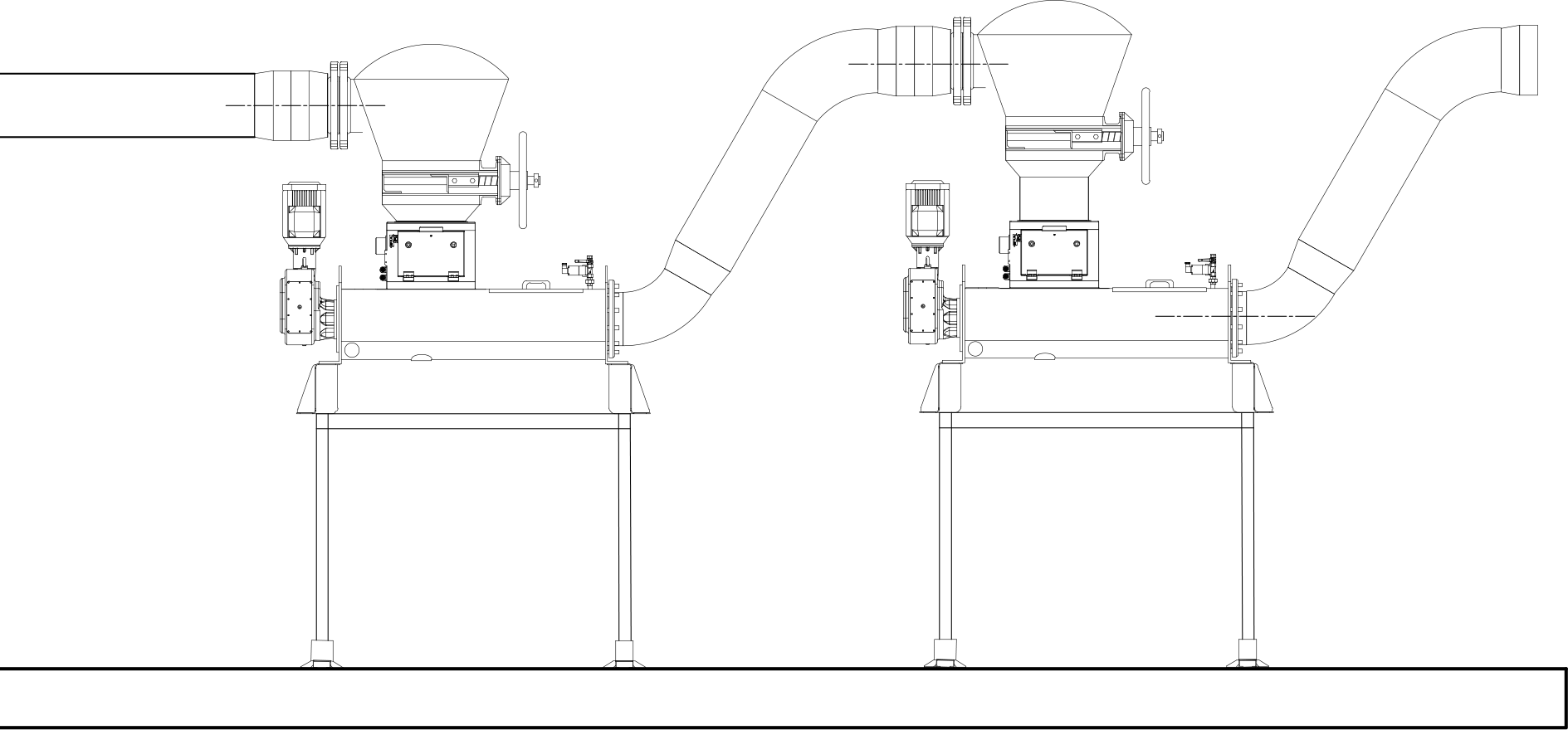

The technology package consists of a high-yield small-scale biorefinery and bioethanol blend system operating in continuous mode using state-of-the-art control technology.

A versatile technology using different agricultural residues such as straw or bagasse and their mixtures, guaranteeing all-year operation. Capacities are adjusted to the community’s agricultural residues availability, from 5 to 200 tons per day. With fast deployment times, competitive production costs, and indirect costs lower than fossil fuels, there are no similar competitors in the market. The gasoline-biofuel blend can be sold in local gasoline stations.

The biorefinery is composed of continuous biomass conditioning, pretreatment, co-saccharification-co-fermentation, and bioethanol purification in semi-automatic mode. Waste and water treatment can be included. Continuous blending with fossil gasoline for local selling is fully automated. The bioethanol production train fits in the same space as a tennis court.